Geothermal Project Solution for a Residential Development in Sommerach

A project solution using locally generated electricity to operate near-surface geothermal energy installations for a new 35-plot residential development of detached and semi-detached houses was completed in the village of Sommerach, Bavaria. The client had called for a CO2-neutral residential development with heating and air-conditioning systems that gave off no fumes, fine dust or noise. To meet these requirements, the regional electricity company “Unterfränkische Überlandzentrale” (ÜZ Mainfranken) offered an energy supply concept known as “Cold-Heat”. Geothermal heating design engineers Erdwärme Plus, manufacturer Jansen and drilling company Geowell submitted a joint tender in the form of an overall package for power and heat. JANSEN powerwave single-u ground source heat loops were used in order to achieve the required heat output from fewer and shorter boreholes.

ÜZ Mainfranken

Founded as a result of a citizens' initiative in 1910, ÜZ Mainfranken is an energy cooperative with its headquarters in Lülsfeld, Bavaria. ÜZ Mainfranken developed an energy supply concept, which it calls "Cold-Heat", for supplying households with electricity and heat. This concept is based on the use of regionally generated electricity. A combination of renewable, emissions-free electricity and heat pumps makes use of near-surface "cold" energy. The generated ground heat is brought up to heating system temperature level in an environmentally compatible manner. This technique allows four-fifths of the energy required for heating, cooling and hot water production to be extracted free-of-charge from the ground on which the houses stand.

One-fifth of the energy is drawn from the public grid in the form of renewable electricity. A suitably designed tariff system completes the concept. The energy supplier was awarded the Main Prize of the Bavarian Energy Award in autumn 2018. ÜZ Mainfranken received the award for its "ÜZ – adding value to renewable energy" project. More than 6,350 systems are connected to the grid operated by the energy cooperative, which produces its electricity from renewable sources.

Working with local authorities in its area, ÜZ Mainfranken also developed a means of supplying heat to new building developments through a combination of near-surface geothermal energy, ground source heat loops, heat pumps and combined storage. The overall concept integrates the power and heat sectors. The heat source is handed over to the house builder ready for immediate use. The benefit for the local authority as the client is CO2-neutral residential developments with heating and air-conditioning systems that emit no fumes, fine dust or noise. The sustainable concept will provide energy for several generations. Customers are offered an all-in package: electricity and heat from a single supplier at attractive tariffs.

35 plots for detached and semi-detached houses in the Franconian village of Sommerach have now been built and serviced in what is ÜZ's fifth project of its type (see image below, aerial photograph). The average energy requirement per plot is around 15,000 kWh, which equates to a heat output of approximately 7.5 kW. This required a total of 117 ground source heat loops in boreholes to depths of 30–40 m.

35

plots

117

ground source heat loops

Aerial photograph of Sommerach. Approximately 4,400 metres of ground source heat loops were drilled to supply 35 building plots.

Need to limit borehole depths

The project was originally designed to use conventional double-U ground source heat loops to a greater depth.

During the project planning phase, the site for the proposed development had a borehole depth limit imposed. This meant that borehole depths in this area were limited to a maximum of 40 m for hydro-geological reasons. A special solution was required because conventional double-U ground source heat loops are limited in their heat transfer capacity, and the number of boreholes could not be greatly increased on the individual plots due to lack of space: Ground source heat loops with higher heat transfer capacity achieved the necessary heat output even with fewer and shorter boreholes. Based on a geological profile and the technical specifications of the JANSEN powerwave corrugated pipe, Erdwärme Plus created an energy simulation upon which the successful project design was based. Because of their superior heat transfer capacity, the powerwave single-u ground source heat loops from Jansen provided a higher output than conventional loops, allowing the energy requirement to be covered using shallower boreholes.

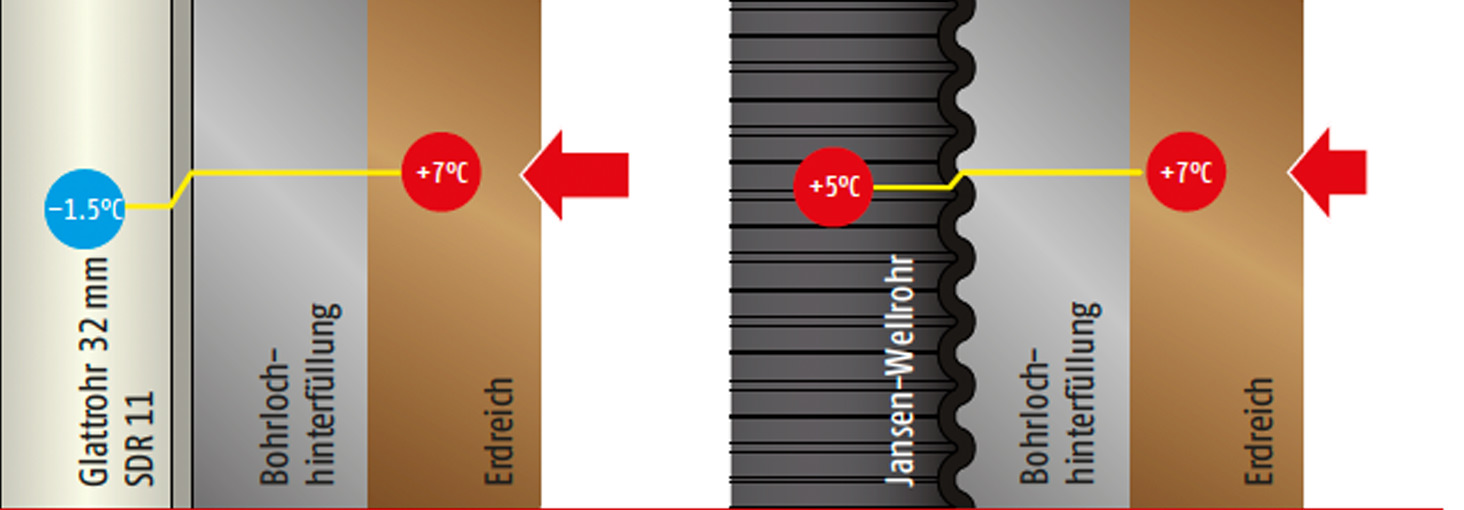

The lower thermal resistance of the "powerwave" corrugated pipe loops leads to a lower temperature loss in the circulating brine (typical calculation).

Fewer and shorter boreholes – how is that possible?

How can geothermal energy be used in an efficient, sustainable and cost-effective manner? The basis comes from nature: the ground is an excellent heat reservoir. Year after year, it naturally absorbs large amounts of solar energy. Just two metres below the surface, the average temperature is already as high as 10 °C. Relatively short ground source heat loops gain from high heat regeneration and the energy reservoir is replenished every year from above. This renewable energy can be used for heating, cooling and hot water production. An important factor in the calculation of the required loop length is “thermal borehole resistance”. This parameter expresses the heat that can be obtained at a defined temperature difference between the ground and the brine. A low thermal borehole resistance results in a higher heat transfer. The JANSEN powerwave corrugated pipe has a particularly low thermal resistance because of its greater surface area and turbulent flow. The design of the plastic pipe was based on research and development work with industry specialists and research establishments including the Institute for Energy Technology (IET) at Rapperswil University of Applied Sciences, Switzerland.

Cost factor – ground source heat loop length

The outer corrugation of the 63 mm diameter JANSEN powerwave corrugated pipe results in a larger heat-exchange pipe surface (0.22 m²/m), which allows considerably more energy to be absorbed from the ground. In parallel with this, the heat transfer from the pipe to the circulating brine medium is improved because the inner corrugation puts the brine into a turbulent state, even at very low flow velocities. The performance of the JANSEN powerwave ground source heat systems can be taken into account in the design of the overall system. This has been shown to result in borehole cost savings.

The powerwave single-u ground source heat loops used in Sommerach have a large storage volume of over 4.5 litres per metre of loop. More energy can be stored temporarily in this large volume of brine. This aspect ensures optimal heat exchange with the ground, even during periods when no brine circulation takes place. The efficiency of the heat pump is significantly increased both at peak load and in cyclic operation. The large pipe diameter also ensures that pressure loss is minimal. In this way, the power consumption of the brine circulating pump is reduced and in turn a higher annual coefficient of performance (COP) for the entire heat pump installation is made possible.

Installation of the ground source heat loops at Sommerach

The boreholes were carefully and precisely bored by the drilling subcontractor Geowell Erdwärme. The ground source heat loops are designed to be simple to install, which proved an advantage. Despite its large diameter, the pipe offers the installer excellent bendability because of its corrugations. JANSEN powerwave is manufactured at Jansen’s production facility in Oberriet out of the latest generation of PE 100 RC and can therefore withstand high loads. Extruded plain pipe segments every 100 cm allow easy cutting to length. This offers full flexibility for assembling customised lengths of loop and secure connections to connection pipes using commercially available electrofusion fittings. The structured surface finish on the corrugated pipe ensures leak-proof, reliable grouting, which results in better vertical bore hole sealing.

Commercially available special reels can be used for installing the loops, which are welded in the factory so that no site welding is necessary. Jansen's special tool for installing the ground source heat loops was made available to the drilling contractor: attachable Jansen heat loop weights allow the loops to be gently lowered into position. Likewise, accessories to aid installation and grouting around the ground source heat loops, including the proven JANSEN SmartTight couplers, were made available.

Other reference projects crucial in ÜZ Mainfranken’s decision

ÜZ Mainfranken considered it highly important for the completion of the project in Sommerach to obtain reliable products from a recognised, specialist manufacturer. In this context, it was helpful to know that JANSEN powerwave single-u ground source heat loops had already been used successfully in other challenging situations. Numerous analyses of earlier projects show that ground source heat pump systems can be designed to be smaller and hence more cost-effective.

Other projects

A design originally based on a 10.6 kW heat output heat pump and two conventional 32 mm diameter double-u heat loops each 125 m long was proposed for a detached house in Schellenberg, Liechtenstein. From the results of thermal simulations, the designers proved that by using JANSEN power wave single-u ground source heat loops, a borehole length of 100 m each was more than adequate, which represented a 20% reduction. Temperature monitoring began from the time the system went into operation at the end of 2015. According to meteorological records, January 2017 was the coldest month for 30 years. However, the measured brine temperatures at the heat pump never fell below +4° C. Another example project in Mannheim shows just how well near-surface soils can perform as an energy source.

Strict borehole depth restrictions applied to a ground source heat pump system for a two-storey end terrace house (newbuild). A 6.1 kW heat output heat pump extracts a nominal 4.8 kW of heat energy from the ground below. A conventional design would have required a borehole depth of 140 m. However, a depth restriction of barely 37 m applied to this site. It would have been illegal to drill down into groundwater resources at this location. So where would the required thermal energy come from? By using two JANSEN powerwave single-u ground source heat loops, a ground source heat pump system could be relied upon to provide heating, hot water and cooling. These projects share a single common feature: out of a situation with supposedly questionable feasibility, it was possible to design a customised ground source heat pump solution that had higher output, required less space and ran less risk of encountering problems during installation.

A plain pipe segment (shown in the centre of the photograph) is integrated every 100 cm along the pipe. This offers full flexibility for assembling customised lengths of loop and secure connections to connection pipes using commercially available electrofusion fittings.