Sustainable energy concept for a sustainable corporate vision

In the major construction project for the new company headquarters of the Hungarian MOL Group, a heating and cooling system based on renewable energies was a key factor. The challenging location of the nearby River Danube and a high groundwater level called for absolutely watertight manifold chambers in an environment featuring heat transfer media circulating at temperatures of up to 45 degrees Celsius. The complete solution made from high-temperature-resistant PE-RT materials comprised 310 JANSEN geotwin shark geothermal probes for a total bore length of 32,800 metres, over 21,000 metres of connecting pipes, more than 2000 electrofusion fittings and six large-scale manifold chambers.

Efficient high-tech geothermal system

The new group headquarters for the listed MOL Group is situated to the south of Budapest city centre and is just a few metres from the River Danube. The 143-metre-tall tower with its 28 floors is one of the tallest buildings in Hungary and the tallest in Budapest. This iconic structure, designed by the renowned architect’s office Foster & Partners, is accompanied by a five-floor office complex named the “MOL Campus”. It was important that the building met the organisation’s functional requirements and the highest sustainability standards, while also blending in with nearby historical buildings at the same time.

With a total floor space of 86,000 m², the building houses 2500 workstations. The lower floors play host to restaurants, a conference centre and a whole host of other facilities for staff, while the flexible office rooms are situated in the upper floors. With the help of the latest technology for managing lighting conditions and the temperature, inspiring rooms featuring plenty of natural light are created as the perfect working environment. MOL operates in more than 30 countries around the world and has won sustainability prizes in the areas of corporate responsibility, sustainability and corporate governance. The new building aspires to achieve LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) certification. The construction of the campus began in 2019, the drilling work was completed in 2020 and the commissioning of the “MOL Campus” property is scheduled for 2022.

310

geothermal probes

32800

metres total bore length

21000

metres of connecting pipes

2000

electrofusion fittings

Special situation – 45 degrees Celsius in the underground

The sustainable approach for the building complex is based in every respect on the latest technologies. This also includes the subsoil – one of the main factors was a heating and cooling system based on renewable energies. One-third of the enormous amount of energy required to provide heating and cooling is provided by geothermal energy, with the basic load provided continuously throughout the entire year. The leading planning and drilling company Geo Concept designed the geothermal heating and cooling system in line with the building requirements.

Two large Carrier Aquaforce heat pumps provide 2.2 megawatts of heating and cooling power. Before a thermal simulation was able to be carried out to dimension the field of boreholes with the EED software, a thermal response test (TRT) of the substrate was performed. This not only provided important information on thermal conductivity, but also unearthed a special hydrogeological situation: During the TRT, temperatures of 45°C were measured at a depth of 120 m. This meant that only high-temperature geothermal systems that are absolutely reliable in terms of long-term durability were able to be used at this location. The sustainable overall concept drawn up by Jansen comprised JANSEN geotwin shark geothermal probes as well as pipes, manifolds and fittings made from high-temperature-resistant PE-RT. From the probes to the heat pumps via the chambers: a complete system that allows for 45°C water to be circulated constantly for a service life of 50 years.

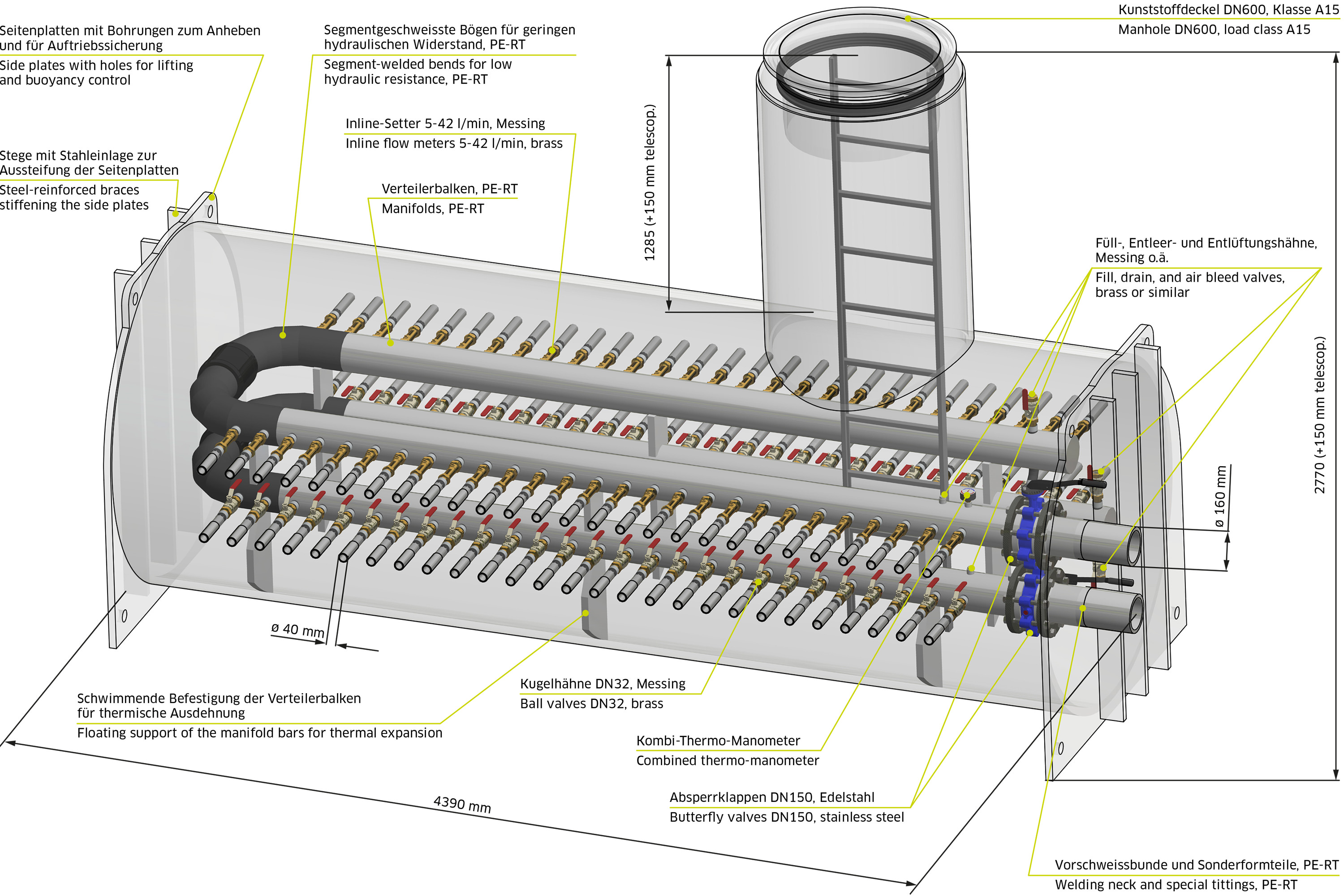

Due to the foundations no geothermal probes were placed under the tower. These were installed in other locations, i.e. 220 probes were placed at a depth of 100 metres underneath the five-floor office complex and 90 were installed at a depth of 120 metres next to the building. All in all, this means 32,800 metres of geotwin shark U loops. Using more than 21,000 metres of PE-RT pipes, these heat exchangers were connected to the plant room. In comparison, Lake Balaton in Hungary is approximately 79 kilometres long, which means all of the pipes installed in the MOL Campus could stretch from one side of the lake to the other. The probes are connected via six manifold chambers; the largest chamber holds 55 circuits and is 4.5 metres long.

Jansen: supplier and partner

Jansen fulfilled all of the requirements from the geothermal probes to the manifold chambers and connecting pipes – resistant to high temperatures, energy- and resource-efficient, reducing operating and investment costs, resistant to pressure, watertight and absolutely safe. The MOL Campus is scheduled to be supplied with geothermal energy from 2022 onwards. Clean, without any odour or noise emissions and no visual restrictions – it is a sustainable, environmentally friendly solution.

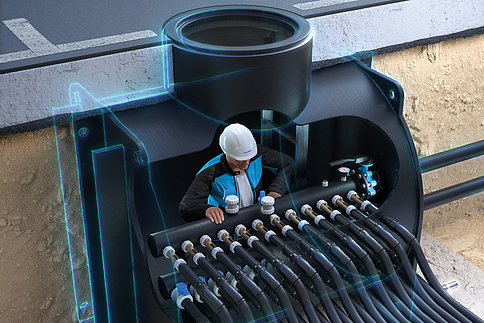

Six drilling teams are working in parallel inside and outside the 16 metres deep excavation pit. At the same time, drilled probes are already connected to the shafts and elsewhere, the installed pipes and shafts are covered with the ground slab by the following trade.

Piecework installation in a 16-metre-deep construction trench

Six drill rigs were used and 20 qualified welders worked in parallel shifts. Márton Gallai, Project Manager at the market-leading drilling company Geo Concept had the following to say:

«It was hard work organising the project and avoiding conflicts with other work processes and trades. Both the client MOL and the general contractor Market require absolutely precise work. To ensure this, we relied on Jansen as a reliable supplier and advisor. As a result, the tight deadlines were able to be fulfilled and the geothermal project successfully completed.»

Geo Concept also received professional support in the design of the chambers in terms of watertightness, stability and the dimensions. The construction pit for the six-floor office building situated next to the tower is a remarkable 16 metres deep and contains four underground levels – added to this is the fact that this is next to the River Danube and its high groundwater level. Absolutely watertight chambers were of paramount importance. The office building stands on a 1.2-metre-thick concrete foundation slab, which meant that the access to the manifold chambers, the sealing and the absolute structural reliability were major concerns. With the groundwater pressure in this area, it is vital that the chamber remains stable for decades and does not suffer any deformation, because any subsequent repair work below the foundation slab would be inconceivable. The chambers were tailored to the project and were outfitted at the manufacturing plant with PE-RT high-temperature manifolds. Six manifold chambers were used, with the largest chamber, which is shaped like a horizontal “submarine”, holding 55 probe circuits and measuring 4.5 metres long. The order also comprised more than 21 km of JANSEN PE-RT connecting pipes with a diameter of 40–160 mm as well as over 2000 straight and angled electrofusion fittings and PE-RT moulded parts.

Systems/products

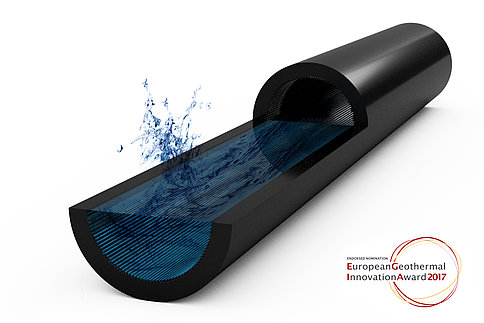

Particularly energy-efficient geothermal probes

In order to fulfil the dimensions of the construction project and the requirements of the owners – energy-saving, resource-efficient and absolute safety – the JANSEN geotwin shark geothermal probe in a PE-RT design was the perfect system solution. This top-of-the-range technology was tailor-made and offered as a complete system. This high-tech system is based on the JANSEN geotwin probe type with the unique and patented double pipe winding. This geothermal probe is renowned for its simple and secure installation and can be identified via its serial number. This ensures that the raw materials can be fully traced until they reach the construction site.

The MOL building needs an efficient system that can provide heating and hot water, as well as cooling in the summer. With this size of building and due to the continuous fulfilment of the basic load, we expect the system to be working for long periods of time, which makes the increased efficiency of the geothermal system even more important, because the longer the circulation pumps are operated, the greater the positive effect the energy-efficient components have on the annual costs.

The decision to use the JANSEN shark technology with the JANSEN geotwin U loops thus provides massive benefits for the hydraulic efficiency of the entire heat pump system. The innovative system comprises a patented surface structure on the interior of the pipes, which imitates the scales of a shark. This has a particularly positive impact on pressure loss in the geothermal system. The surface structure on the interior of the plastic pipes is optimally adapted to the flow behaviour of the circulating medium and thus helps to significantly reduce hydraulic resistance. Pressure loss can be reduced by 7% in comparison with conventional plain pipes. This will have an immediate positive impact on the pumping capacity required and thus on the power consumed by the circulating pump. At the same time, the modified interior surface also provides for a lower filling volume, which in turn reduces the amount of heat transfer medium needed. Filling is thus approximately 4% cheaper than with conventional plain pipes.

The six individually manufactured manifold chambers had to be completely water-tight and pressure-resistant. The distribution systems are made entirely from high-temperature resistant components.

The largest JANSEN ‘U-Boot’ manifold chambers are almost 4.5 metres long and include up to 55 geothermal probes.

Statement

A project of this magnitude is always an organisational challengetoo. In order to keep to the tight schedule, the market-leading drilling company Geo Concept and the general contractor Market put their faith in Jansen as a reliable supplier and adviser.

«Jansen has been one of our best partners for years. For this project we had to overcome a couple of very specific situations. This meant we needed a supplier that could not only provide us with individual advice but also deliver high temperature-resistant products. We also had professional support when designing the chambers under the 1.2-metre floor panel in relation to waterproofing, stability and size. Whenever I had a question, the technical team at Jansen were able to provide me with reliable information in a short space of time. Sometimes things can change very quickly on the construction site or you have to react to a problem. Whenever we had challenging deadlines to meet, nothing was too much trouble for Jansen. It is always a pleasure working with Jansen.»

Márton Gallai, Project Manager Geo Concept

Contact

Do you have any questions regarding our products or services?

If so, please don't hesitate to contact us!

Plastic solutions contact partners