Jansen flow drilling tool box

Efficient metalworking

Jansen flow drilling tool box revolutionises your production processes

Are you looking for an efficient and precise solution for processing your Jansen window and door systems in steel and stainless steel? Our new, customised flow drill was developed to support metalworking companies in optimising and accelerating their production processes.

Set 499.023 consisting of:

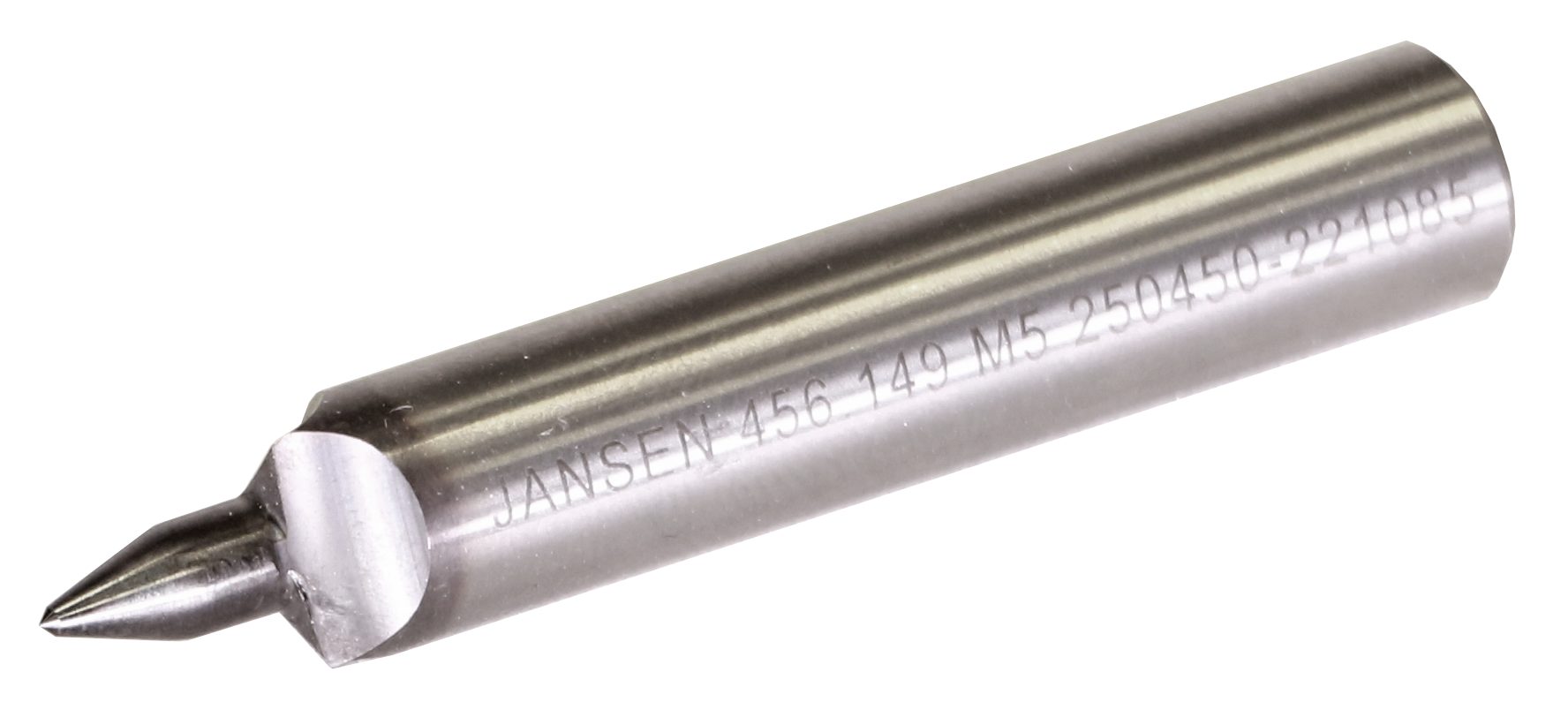

- Flow drill 456.149

- Centre punch for drilling jigs 456.023

- Vertical stop 456.150

Areas of application

Flow drilling is used in the thin sheet metal sector for sheets up to 2.4 mm thick. In the next work step after making the extruded holes, the tried and tested thread-forming screws from Jansen can be used.

Advantages of flow drilling

- No additional work step required for thread forming

- Stable threaded connection without additional materials such as blind rivet nuts

- Direct use of our proven self-tapping screws after flow drilling

- Cost and time savings compared to conventional methods such as pull-in nuts

- No release agent required for flow drilling

- Enables high pull-out forces

- Chipless, without waste

Case material

Outside: a robust plastic cover; the inside is lined with foam.

Specially developed flow drill

Flow drills are used where special demands are placed on tear-out resistance, e.g. when attaching fitting components.

Our flow drill was specially developed for metal fabricators who process our window and door systems. It is longer than the standard flow drill and for M5 threads. With a shank diameter of 10 mm, it can be clamped in a box column drill as well as on a machining centre. It is suitable for wall thicknesses in the thin sheet range up to 2.4 mm. The tool is designed for dry machining without release agent. The additional cutters are used to remove the burr to ensure a flat surface for attaching the add-on parts. The burr removal is limited by the depth stop when machining with the box column drill.

Functionality

The flow drill generates mechanical friction via the spindle speed. This heats the base material and displaces it in an axial direction. The result: An extruded hole from the base wall thickness is moulded - completely chipless. This sleeve is significantly longer than the original material thickness and can then be used as a stable threaded connection with high pull-out values.

Which self-tapping screws can be used?

| 557.360 Countersunk screw | M5 | 12 | Countersunk head | TX20 | carbon steel E-look thread-forming |

| 557.361 Countersunk screw | M5 | 16 | Countersunk head | TX20 | carbon steel E-look thread-forming |

| 557.362 Countersunk screw | M5 | 20 | Countersunk head | TX20 | carbon steel E-look thread-forming |

Our tool box is the ideal solution for neatly storing tools and contains:

- 1 x flow drill 456.149 (tool for creating an extruded hole)

- 1 x centre punch 456.023 for drilling jigs (centre punch to be able to continue using existing drilling jigs for locks etc.)

- 1x vertical stop 456.150 (to limit the drilling depth when flow drilling by hand)

The flow drill is versatile and is suitable for CNC machining as well as for manual use with a box column drill. The centre punch is used for manual processing to mark the holes precisely in advance with our Jansen drilling jigs. The vertical stop makes it easy to set the drilling depth when used manually with the box column drill.