JANSEN shark

Intelligent pipe technology: refined symbiosis of nature and engineering

With more than 60 years of experience in the development and manufacture of innovative plastic systems, Jansen, as a Swiss industrial business, stands for both the highest quality and precision and for pioneering high-tech solutions. Thanks to intensive research in the area of fluid mechanics, Jansen has increased the efficiency of ground source heat systems to a new level.

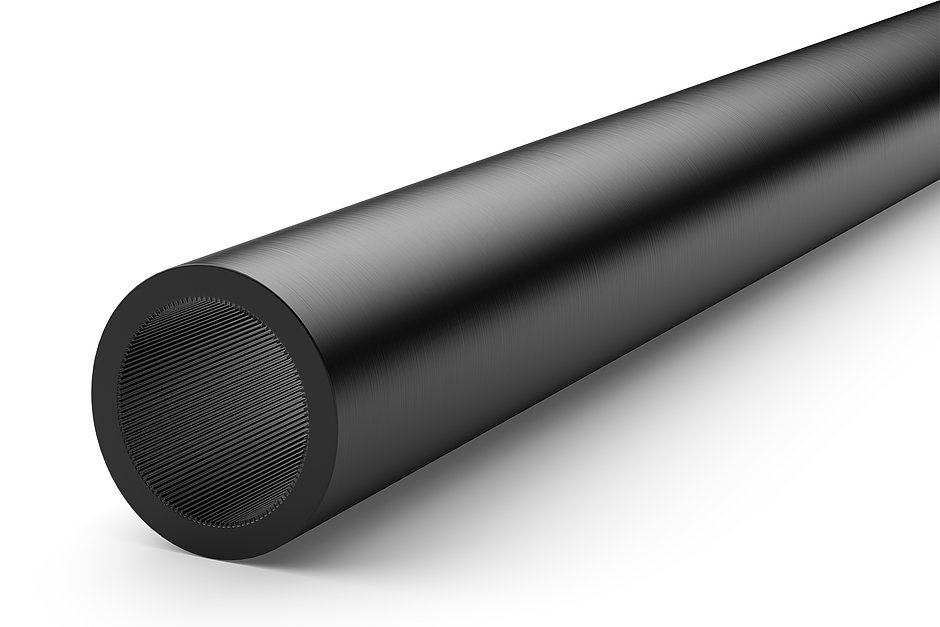

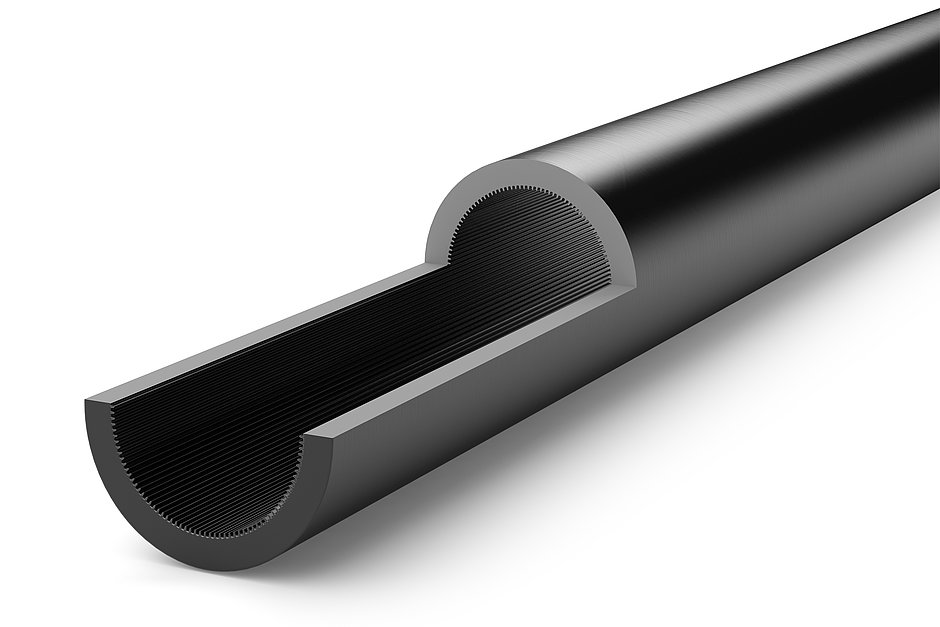

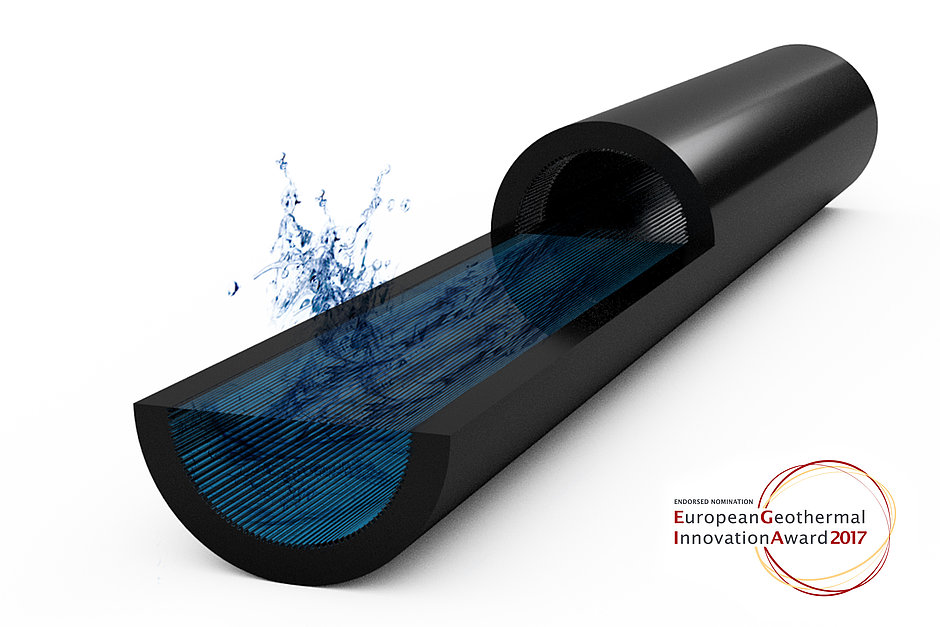

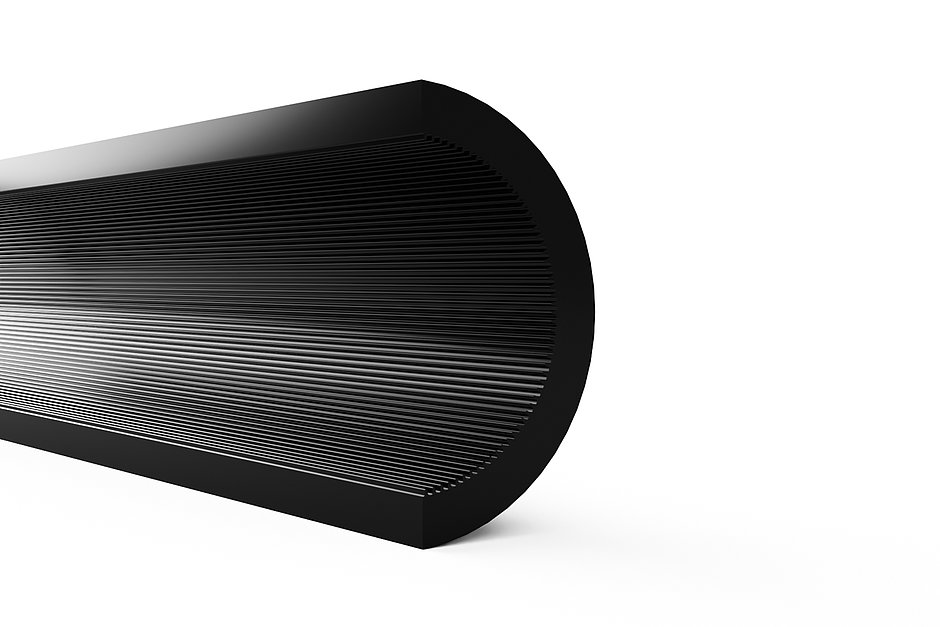

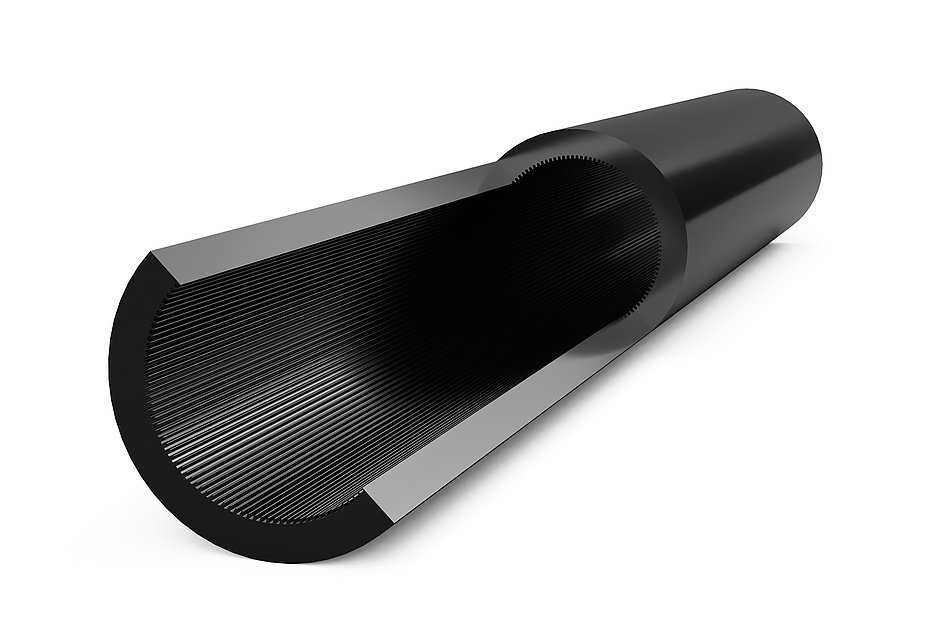

In co-operation with the Institute for Energy Technology at the University of Rapperswil "IET/HSR", Jansen has developed a plastic pipe that imitates the resistance-reducing effect of shark's skin: JANSEN shark technology. The inner structure of the pipe is optimally adapted to the flow behaviour of the circulating brine medium and in this way significantly reduces the hydraulic resistance.

Pipe material

Pipe material PE 100 RC (polyethylene resistant to cracking)

in accordance with PAS 1075

Continuous operating temp.

-20° C to +40° C

Rec. minimum laying temp.

-10° C

Dimensions

| Dimension | Pressure rating | Capacity per metre pipe |

|---|---|---|

| 32 x 2.9 mm | PN 16 | 0.517 l |

| 40 x 3.7 mm | PN 16 | 0.802 l |

| 40 x 4.1 mm | PN 18 | 0.762 l |

| 40 x 4.5 mm | PN 20 | 0.725 l |

| 50 x 4.6 mm | PN 16 | 1.255 l |

| 50 x 5.6 mm | PN 20 | 1.135 l |

| 50 x 6.9 mm | PN 25 | 0.988 l |

| 50 x 7.9 mm | PN 30 | 0.881 l |

Reduced pump power

Compared to conventional smooth pipes, the pressure loss can be reduced by 7 %. This reduction has an immediate positive effect on the pump power required and therefore the power consumption of the circulating pump. Systems with JANSEN shark technology can save between 10 % and 15 % in electrical power, depending on the efficiency curve of the brine pump.

The usual thermal design

The increased surface area for heat exchange inside the pipe produces the usual excellent heat flow even on pipes with a higher pressure rating and therefore thicker pipe wall. As such the planning and design phase is reliable and straightforward using conventional parameters.

Familiar handling

The dimensions of the JANSEN shark ground source heat pipes correspond to common pipe types. The pipe material used, PE 100 RC, is of the highest quality and permits straightforward connection, e.g. with the aid of electrically welded sleeves. Installation is as straightforward and reliable as normal.

Better filling

The modified inner surface finish results in a reduced filling volume. For this reason, less heat transfer medium is required overall. Anti-freeze is expensive; with the JANSEN shark ground source heat systems, filling is also around 4 % less expensive than with conventional smooth pipes.

- Ground source heat loops

With JANSEN shark technology, ground source heat loops benefit from a lower pressure loss, irrespective of the depth and design. Small pipe dimensions can generally be used for deep ground source heat loops because JANSEN shark technology compensates for the increasing pressure loss with increasing heat loop length. Along with the increased efficiency of the circulating pump, reduced operating costs and easier installation, this aspect also has a positive effect on the overall investment costs. - Connection lines

The lines for the connection of ground source heat loops to the heat pump can contribute up to one third of the total pressure loss on the usage of normal smooth pipes. JANSEN shark technology can also be used for these pipes to improve the overall efficiency of the system significantly. The operating costs are minimised, the payback period reduced. -

Ground source heat exchangers

Horizontal heat exchangers also profit from a lower pressure loss. With JANSEN shark heat exchanger pipes, longer brine circuits are possible without problems. This situation results in simplified installation and a smaller and therefore less expensive distribution system.